Zwergle

Waschanlagen > Anlagen für den Rotationsdruck

“Zwergle Duo Special” for Storopack

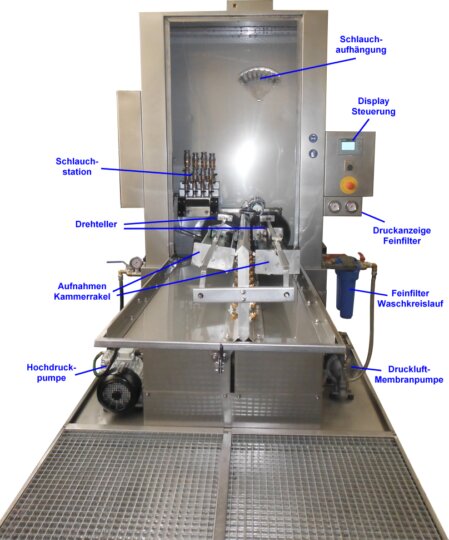

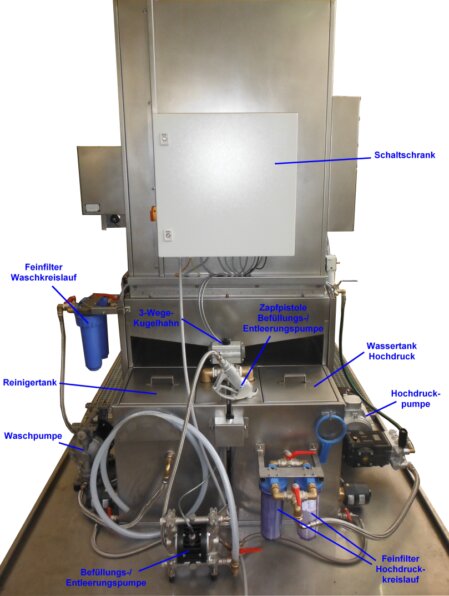

Rotary cleaning system for max. 2x chamber doctor blades and 4x hoses

- 2x turntable with universal holders for chamber doctor blades with a maximum length of 1250mm

- Switchable hose station for cleaning a maximum of 4 hoses (1/2", 3/4" and 1")

- 2x tanks with integrated thermostat-controlled screw-in heaters (6kW)

- Washing circuit (main wash) with alkaline cleaner (temperature approx. 55°C) and 1" compressed air membrane pump

- High-pressure circuit (rinsing) with water (temperature approx. 30°C) and high-pressure pump (7kW, 30l/min at 100bar)

- Siemens LOGO PLC control with control panel

- 2x redundant fine filter cartridges in each washing circuit

- 1x filter drawer each in the return line to the tanks

- Additional 1/2" diaphragm pump for filling/emptying the tanks

Rotary screen cleaning system "Zwergle-Duo/Universell"

Leonard Kurz Foundation

- with 2 dockable containers for washing and rinsing integrated in the floor pan

- blow-out device

Rotary printing stencil cleaning system (custom-made for Freudenberg Performance Materials Apparel SE & Co. KG)

- max.stencil length 2400mm

- 2x high pressure plunger pumps

- 50x Lechler high pressure nozzles

- Required connections: electrical connection 400V / 16A

- House water supply line min. 80 l / min

- Compressed air connection

- Sewage connection

Watch on YOUTUBE

Simple cleaning system for rotary screens "Zwergle"

Available in 3 versions:

> Zwergle / 1 (standard) for 1 rotary screen

> Zwergle / 2 with compressed air-operated turntable for different screen diameters and widths

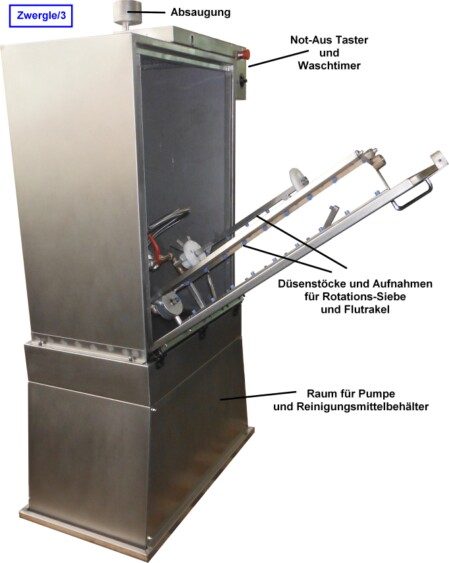

> Zwergle / 3 for 1 rotary screen and station for 1 flood squeegee

- 2 utility models:

> Docking device for 25 or 30l canisters No. 20.2010.014 135.4

> Drive wheel for rotation No. 20 2011 005 529.9

- ATEX version

- pneum. control

- pneum. washing pump

- Adjustable screen inclination (better dripping behavior)

- Extraction via Venturi nozzle (exhaust air line required on site)

- mechanical timer for washing time

- mechanical timer for blow-out time

Commissioning in approx. 10 min.

> Set up the 'Zwergle at the destination, connect compressed air and exhaust air, dock a full detergent canister, put in the rotary screen, close the lid, set the washing time and off you go ...

Zwergle / 2:

Cleaning system for rotary screens with different screen widths and diameters

- with compressed air driven turntable (protection of use no.20 2011 005 529.9)

- Docking device for cleaning canisters on the side

Zwergle/3:

System for cleaning 1 rotary screen and 1 flood squeegee